Do you know the feeling when a stud snaps onto the windshield and creates a crack? Luckily, there’s glass insurance, or is there?

In Finland, cars face rather harsh conditions. Frost, gravel, studs, road chemicals, etc. Protecting the paintwork has been popular, and a similar product has been developed for glass surfaces.

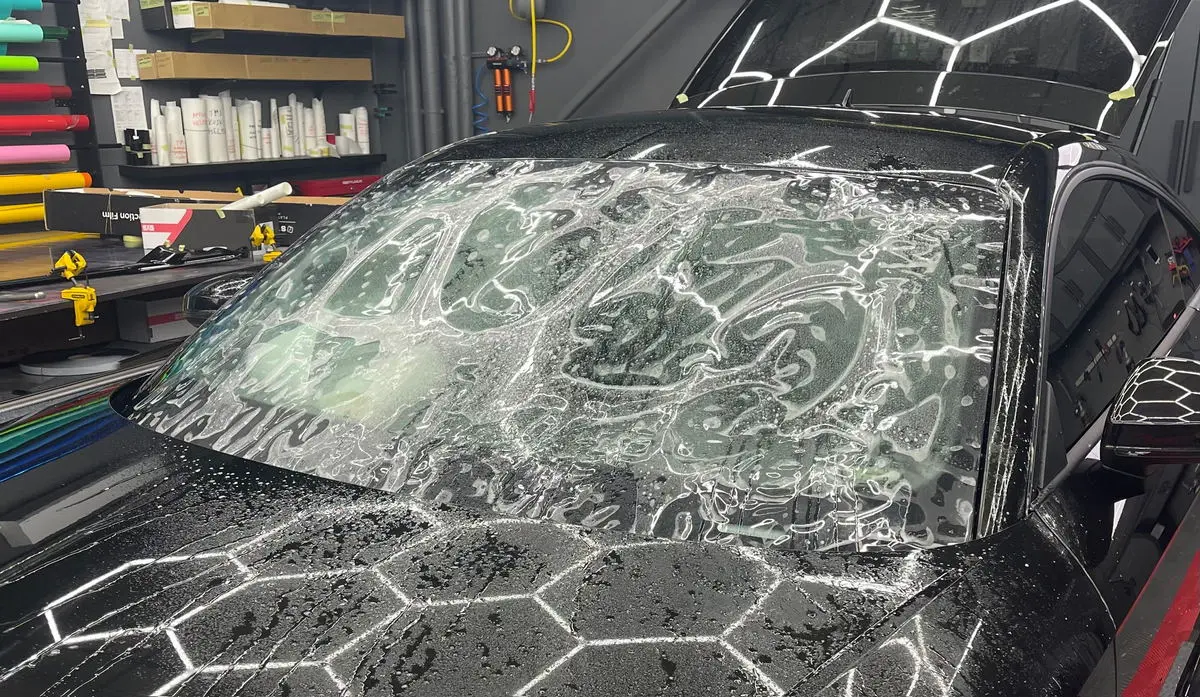

Windshield protection films are a relatively recent innovation in the industry, offering the possibility to cancel glass insurance. Windshield protection films have been proven to protect against stone chips and studs, absorbing the impact themselves and preventing them from causing damage to the windshield.

This recent invention also has its delicate aspects, which we will uncover in this article, honestly and openly, based on our own experiences as well as those of our customers.

Categories of Protection Films

Windshield protection films are currently divided into two categories: hard and soft films. Each has its own characteristics to consider.

ClearPlex protective film from the American manufacturer Madico is made of hard PET material, which requires shrinking with a heat gun. This type of film has been on the market the longest.

+ Due to its hard surface, it is not scratched as easily and quickly by windshield wipers as soft films.

+ Wide roll sizes (152cm and 183cm) allow for the protection of larger windshields, such as buses and trucks.

– Slightly weaker adhesive compared to soft films, which is evident when a pressure washer is directed too closely towards the edge.

– Installation for highly curved windshields is extremely challenging and requires training and experience from the installer, e.g., Tesla Model 3. With hard film, Restyling Point has installed 10 Tesla Model 3 windshields and found that the soft material is better.

Renowned film brand Stek has created a rather innovative product called DynoFlex, which, despite its phenomenal advantages, also has its weaknesses.

+ Extremely easy and quick to install, which positively reflects on the customer’s final invoice.

+ Very good adhesive grip and durability even with incorrect washing methods, such as pressure washer proximity to the edge.

+ Due to its elastic surface, absence of stone chip marks since the film regains its elasticity. Thus, it operates largely identically to a paint protection film (PPF).

– Limited roll size, 122 cm, which may restrict the protection of some vehicle windshields or require using two pieces. For example, in Tesla Model Y, the windshield extends quite far under the hood. To protect the entire glass surface, you may need to add a strip hidden under the hood, though it’s a place impossible for stone chips to reach.

– Prone to scratching relatively quickly in regular use (approximately 20,000 km/year) within 9-12 months if washing the car once a month and not maintaining the windshield wipers. Scratches may cause slight discomfort, especially in sunny weather.

– Minor blur effect, which the eyes adapt to after 1 week.

Due to its higher material cost, this reflects in a higher amount paid by the customer compared to ClearPlex (if the car’s windshield shape allows for ClearPlex installation).

From a scientific perspective, considering the laws and facts of physics, the task becomes particularly challenging because if we want a film with perfect scratch resistance, the film should be closer in hardness to glass. Conversely, if we want a film that effectively repels stone chips without leaving marks on the film’s surface, the film should be as soft as possible, like paint protection films.

At Restyling, we believe that the future lies more with soft films because the first version of the soft film differs greatly from the 2023 model. That is, soft films have improved their composition and performance during their update versions.

The conditions in Finland are harsh for both types of films. In Central Europe, these products serve for a longer duration.

The benefits of windshield films:

Films developed for windshields are designed to withstand the stress on the front of the car caused by stone chips, studs, and all the daily wear and tear that would normally affect the windshield.

The film absorbs all the stress, preventing it from reaching the glass itself.

Without a protective film on the glass, the windshield would wear and break more easily, requiring replacement. When replacing a windshield, there’s often a risk of damaging seals, which could lead to rusting in adjacent areas of the paintwork. The windshield replacement process takes the car out of use for a while, causing inconvenience.

Especially for collector cars, the original factory glass, if in pristine condition, often adds value. Preserving this originality can be invaluable in the future.

For instance, in motorsports, windshield protection films are extensively used for safety reasons. When a car comes into the pit stop, one layer of the protection film is peeled off. There can be up to 10 layers of protective films stacked on top of each other on cars.

Weaknesses of Windshield Films

Films cannot endure continuous wiping of windshield wipers indefinitely because the material of the film is plastic or polyurethane, and it scratches due to the sand on the glass. Although Restyling includes two layers of ceramic coating on top of the film during installation, the film still gets scratched. The product has not yet reached sufficient maturity.

After driving with the film for an average of 9-12 months, scratches start to impair visibility from inside to outside, especially in sunny weather. We have tried to polish the film using various methods, but the maximum improvement in visibility has been around +20%, meaning that the unpleasant visibility from inside to outside persists even after polishing.

The film doesn’t lose a percentage of its protective ability when scratched.

As a theoretical option, the film’s lifespan could be extended by reducing the number of scratches with regular car washing and changing wipers once a month. But in this theory, there’s no logic or even a temporal possibility, considering that people have other things to do in life.

Windshield protection films get scratched when scraping ice in frosty conditions. Therefore, preheating the car or using widespread remote-controlled interior heating is advisable to avoid scraping ice from the windshield.

Blur effect. This feature is present in fresh films, meaning that when looking from inside to outside, a blur effect may be visible through the film. This is a normal phenomenon, and statistically, the eyes adapt to it within 1-2 weeks. Initially, this may be an uncomfortable feature, but there is no need to worry as one gets used to it. The blur effect is caused by an additional layer of protection film on the glass surface.

So, how well does the film withstand on windshields? Here is an example: www.instagram.com/p/CPDF0mjg-s6

Windshield Protection Film Price

The installation of a windshield protection film typically costs between €500 and €700 on average. The shape, curvature, and trim of the car’s glass affect the price.

Example price list:

– Mercedes-Benz G-Wagon: €399 (straight glass, narrow and small size)

– BMW X5: €699

– Tesla Model 3: €790 (large curved size. Can be done most affordably with soft DynoFlex. with hard ClearPlex material €1290)

Installation requires overnight drying to meet warranty conditions. The installation fluid and the ceramic coating applied to the film need to dry and harden.

Comparison of Windshield Protection Film vs. Glass Insurance Costs:

Theoretical calculation, based on factual statistics, allows us to determine which option is more cost-effective: **film or insurance**. If the car is driven for 5 years at 20,000 km per year. (excluding summer cars driven only in the summer)

Calculation facts:

– Glass insurance costs on average €50-€250 per year

– On average, one windshield is damaged per year

– Typical deductible for windshield replacement is €200

– Film durability is 9-12 months depending on usage

– Deductibles: €1000 (5 replacements)

+ Free repair of stone chips at a glass repair shop covered by insurance

+ Glass insurance covers other glass surfaces

– Risks associated with windshield replacement

– The original glass is no longer preserved

– Depending on the age of the car, availability may be limited

– Glass damage may affect safety

– Even if the glass never cracks, it may wear to a point where it is full of light stone chips, affecting visibility.

+ No risk of damage to the car body or interior due to windshield replacements

+ Few visible stone chips with a soft film

– Scratching the film while scraping ice in winter; preheating the car is recommended instead of scraping. Not an issue with electric cars or vehicles equipped with Webasto.

– Film needs to be replaced approximately once a year due to scratching from wipers

– Other glass surfaces are not protected/covered as with glass insurance

Summary

Due to their cost, windshield protection films are best suited for:

– Vintage cars, collector cars, or those for which windshields are no longer manufactured

– Essential public vehicles requiring 24/7 operation, such as ambulances, fire trucks, government vehicles, etc.

– Cars driven over 40,000 km per year

– Vehicles with upright windshields, such as Mercedes-Benz G-Wagon, Jeep Wrangler, Hummer, Land Rover, Toyota Land Cruiser, etc.

– Sports cars or vehicles costing over €200,000

Windshield films as a product category are still in their early stages of development. What they can achieve currently is already impressive. At present, film manufacturers simply have not invented a film that is:

– Durable = Does not wear out from windshield wipers in less than a year.

– Transparent = Crystal clear, without the slightest Blur effect.

– Easy to install = Easy to install on curved glass as well.

– Reasonable price = Cheaper, considering the price of glass insurance.

Do you want the work to be done responsibly, on schedule, and with the best value for your money? Ask for a quote from the professionals at Restyling Point, who perform this work with quality standards, values, and love.

WhatsApp: +358445050624

Phone: +358445050624

Email: [email protected]

Restyling Point Oy – The Nordic leader in wrapping and protective treatments