We were tasked with carrying out two almost identical projects. The factory-original white and black Model Y arrived for extensive protection projects.

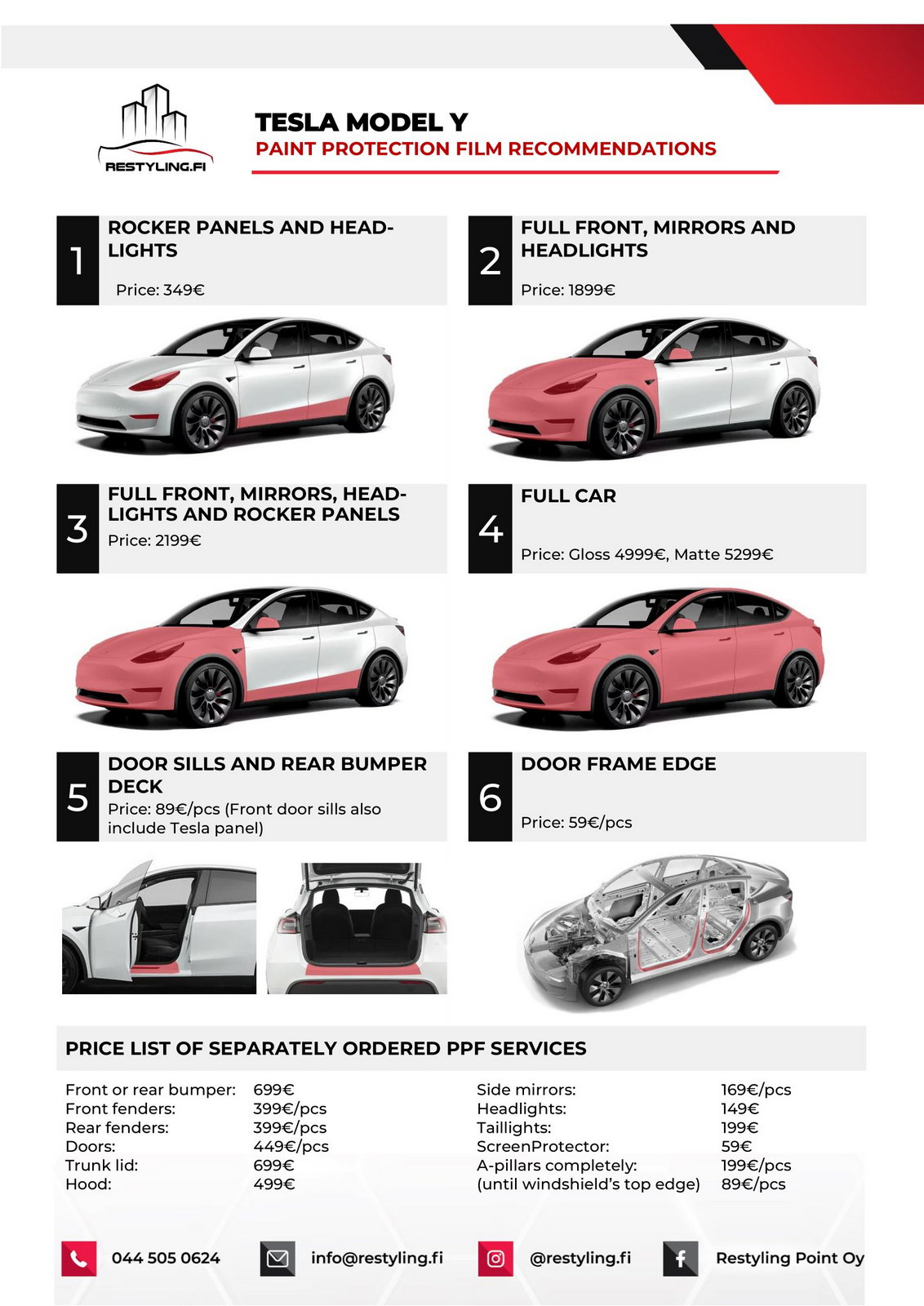

Implemented menu:

- Detailing wash and PPF template modification

- PPF film installation on the paint surface

- Interior threshold protection taping

- Interior tape installations

- Windshield protective film installation

- Ceramic coating

- Window tinting

- Troubleshooting / AfterCare

- Photos of finished Tesla Model Y wraps

- Price breakdown

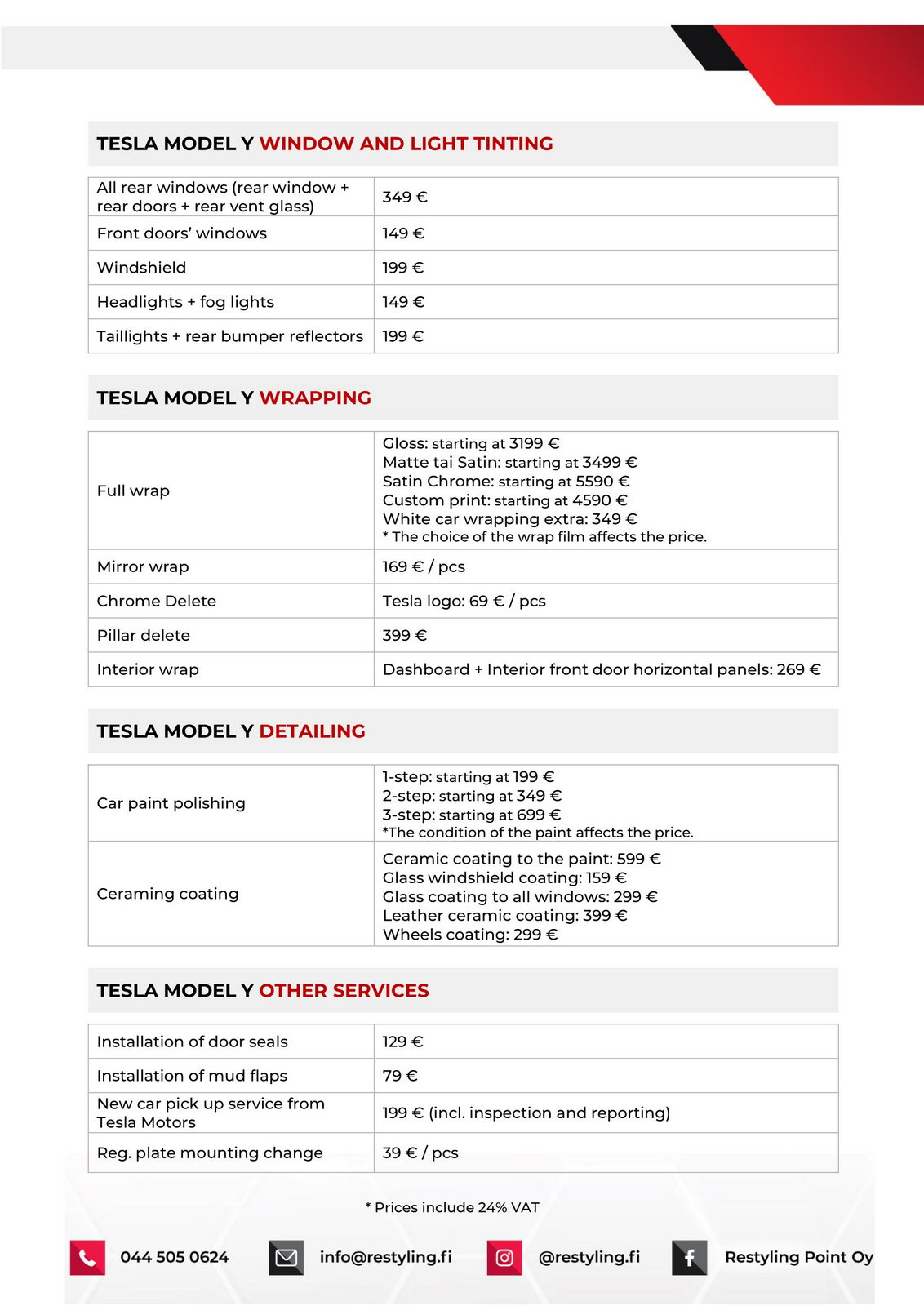

Detailing wash and PPF template modification

We started with a detailing wash, where every nook was thoroughly cleaned with a small detailing brush for maximum cleanliness. The inner side of the rims, door gaps, and tire wells were also meticulously inspected for maximum cleanliness. There couldn’t be any dust or sand grains in the car.

Car detailing wash

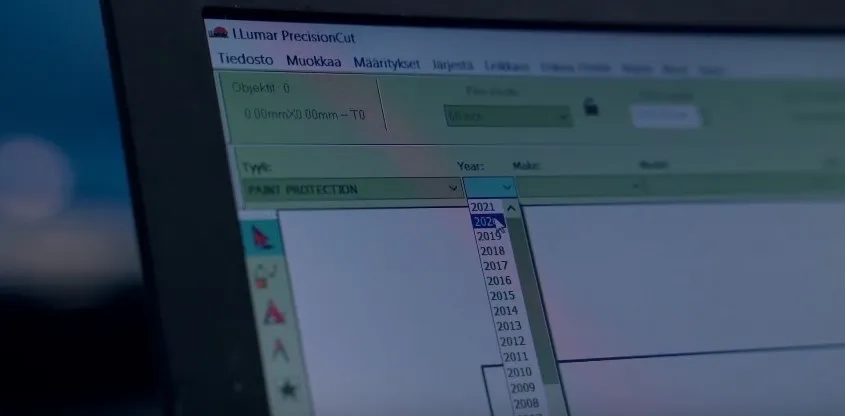

In our Llumar Precision Cut program, templates were modified to fit Restyling’s standards with maximum precision.

Using the Summa D160 tape cutter, we cut 15 meters of matte PPF film and prepared the pieces for installation.

Installation of PPF film on the paint surface

Before the installation, a written scheduling plan was made to anticipate and ensure adherence to the promised timeline for the customer.

The shapes of the car are not inherently challenging, but it presents a fairly standard challenge in terms of complexity.

Thanks to the cutting program, the installation of areas such as door handles was quick and safe. Due to the pre-preparation, we avoided using knives during the process, although it is entirely safe for us to do so. However, we always aim to minimize risk whenever possible.

The curved rear trunk lid was perhaps the only challenging part, requiring the right technical stretching. The trunk lid was successfully covered perfectly in one piece.

Glossy vs. matte PPF

The matte protective film beautifully accentuated the car’s lines and contours, making it appear more sporty and substantial. It enhances the car’s character and sets it apart from the crowd.

Interior threshold protection taping

Following our company culture, discounts are not part of our strategy. Instead, aiming for the “wow” effect, we provide surprise bonuses to our customers, meaning we put ourselves in the customers’ shoes and consider individual complimentary items tailored to their needs. In this case, both customers had children, so we installed transparent protective films on all interior door thresholds to keep them looking new and untouched when the little passengers get into the car.

The front door thresholds also include protective taping for the black logo. For practical reasons, the threshold at the rear is raised slightly higher than usual.

The interior threshold tape was also manufactured from a pre-drawn vector graphic by our graphic designer.

We purposefully crafted the templates for the thresholds to maximize the quality delivered to the customer and to make the installation as smooth and cost-effective as possible, which is also reflected in the price paid by the customer.

Interior tape installations

Not everyone is fond of Tesla’s original wooden trims on the front doors and dashboard, so they were taped to match the seats with Avery Dennison’s Satin Black tape. This minor process brought about a significant change in appearance.

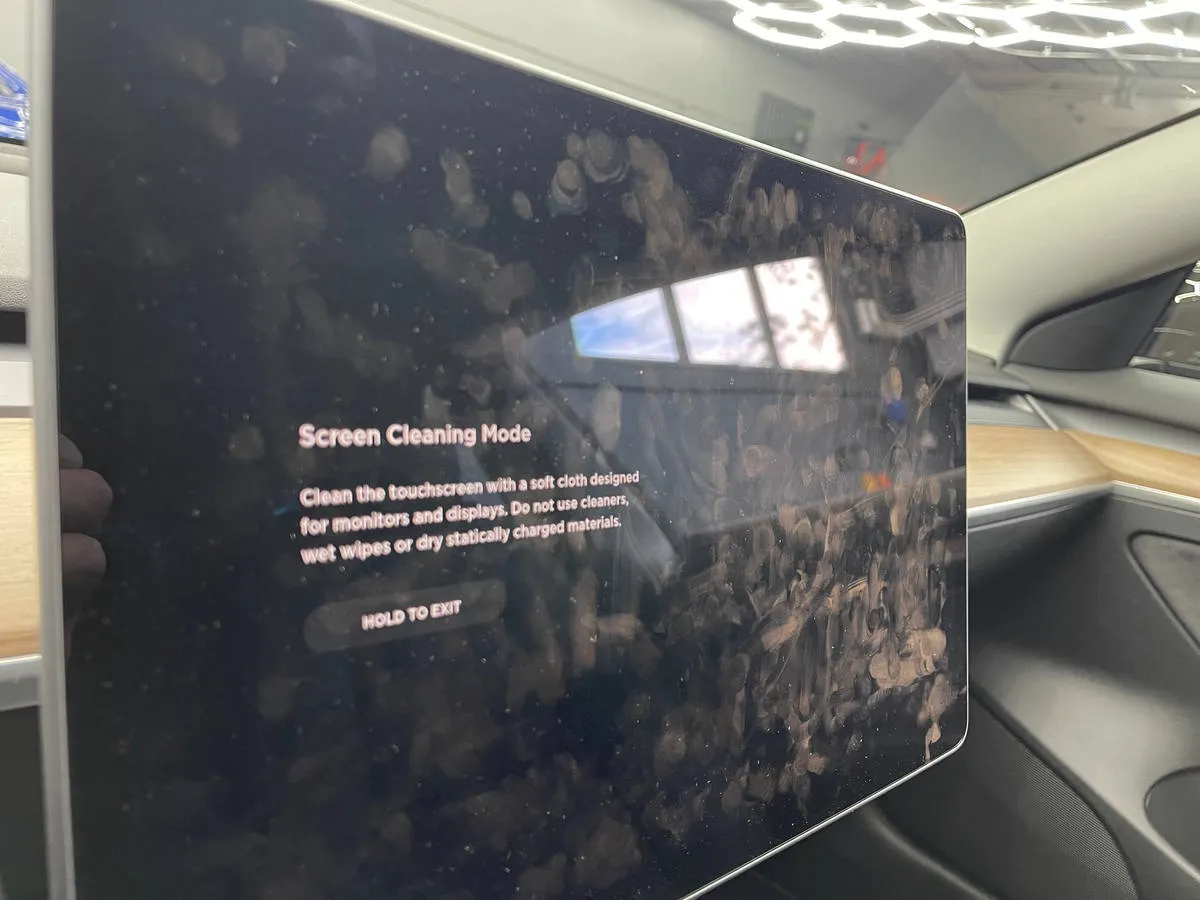

Both cars’ touchscreens were also fitted with individually manufactured screen protectors using computer software, ensuring they remain intact, scratch-free, and free from fingerprints at all times.

For years, we’ve seen touchscreen displays marred with fingerprints and scratches, and we thought there was no solution. Innovative thinking is ingrained in our company’s DNA, so we solved the problem by creating our own screen protector. When installed, it costs less than if a customer were to order a film from AliExpress, pay for customs, and then install it themselves.

Windshield protective film installation

A protective film was also installed on the windshield, similar to PPF but different. Stek DynoFlex is specifically designed and developed for windshields, providing a completely clear, transparent solution that excels at resisting daily wear and tear.

DynoFlex is a revolutionary product in the world of windshield protective films, taking the lead from the former leader, Madico ClearPlex.

Stek DynoFlex offers customers a more affordable price and a better product.

The finishing of the windshield protective film installation is critical for car wash situations and daily use, so it’s important to finish the edges in a way that minimizes the chances of them peeling off. The finishing of the edges is called “trimming” or “edging.”

Ceramic coating

The entire wrapped surface (paint surface) as well as the windshield were treated and protected with a ceramic coating. Ceramic coating helps to facilitate and simplify maintenance. Additionally, the rubber blades of the windshield wipers were treated with the coating to minimize scratching of the windshield protective film.

Matte PPF is porous and absorbs approximately 50% more ceramic coating, thus the material consumption for ceramic coating on a matte car is significantly higher.

Read: What is the difference between ceramic coating and PPF paint protection film?

Window tinting

All Tesla Model Y models come with factory tinted rear windows. They have a tint level of 27%, which is dark enough for many people’s preference.

In contrast, there is no factory tint on the front windows. For this reason, many opt for light 35% tint on the front doors and 70% tint on the windshield. This provides the car with a sleek and polished appearance, without creating a significant contrast with the rear windows.

Although tinting the front windows and windshield is illegal, many still opt for light tint films. This provides an excellent appearance for the car and doesn’t significantly affect visibility.

The factory license plate holders on Teslas are bulky plastic plates that draw too much attention to themselves, detracting from the aesthetic appeal of the car’s front and rear. At the customer’s request, we removed the old license plate frames and installed the license plates onto the car using 3M Dual Lock tape. This gave the car a polished and stunning appearance. Dual Lock attachment is popular nowadays.

Troubleshooting – AfterCare

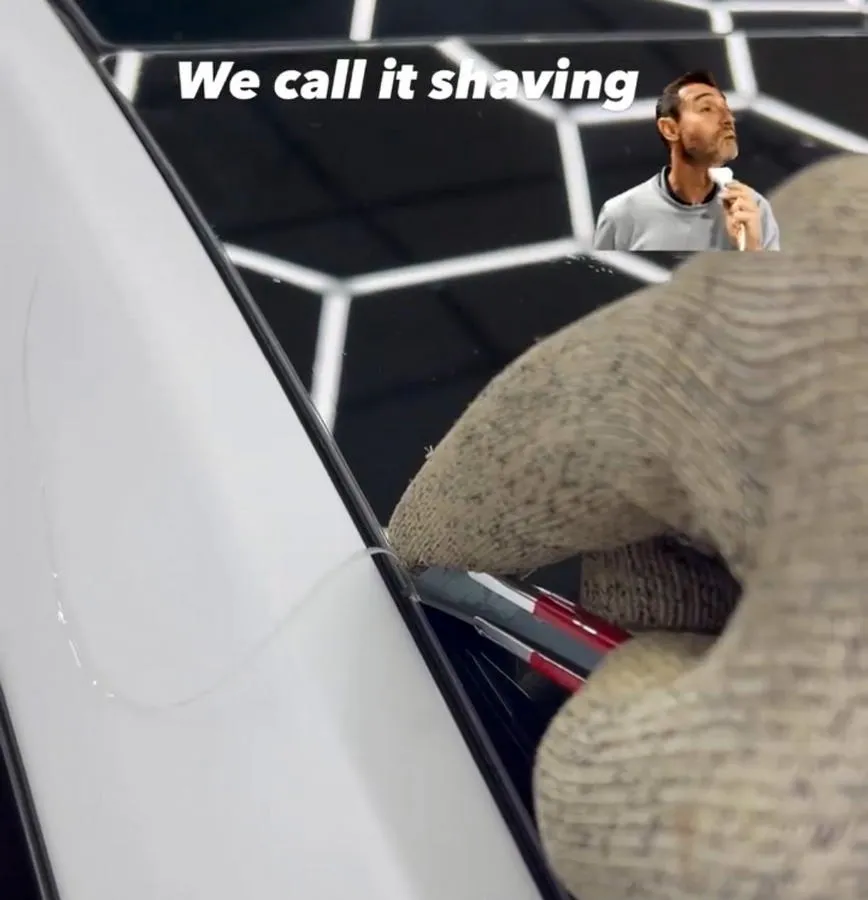

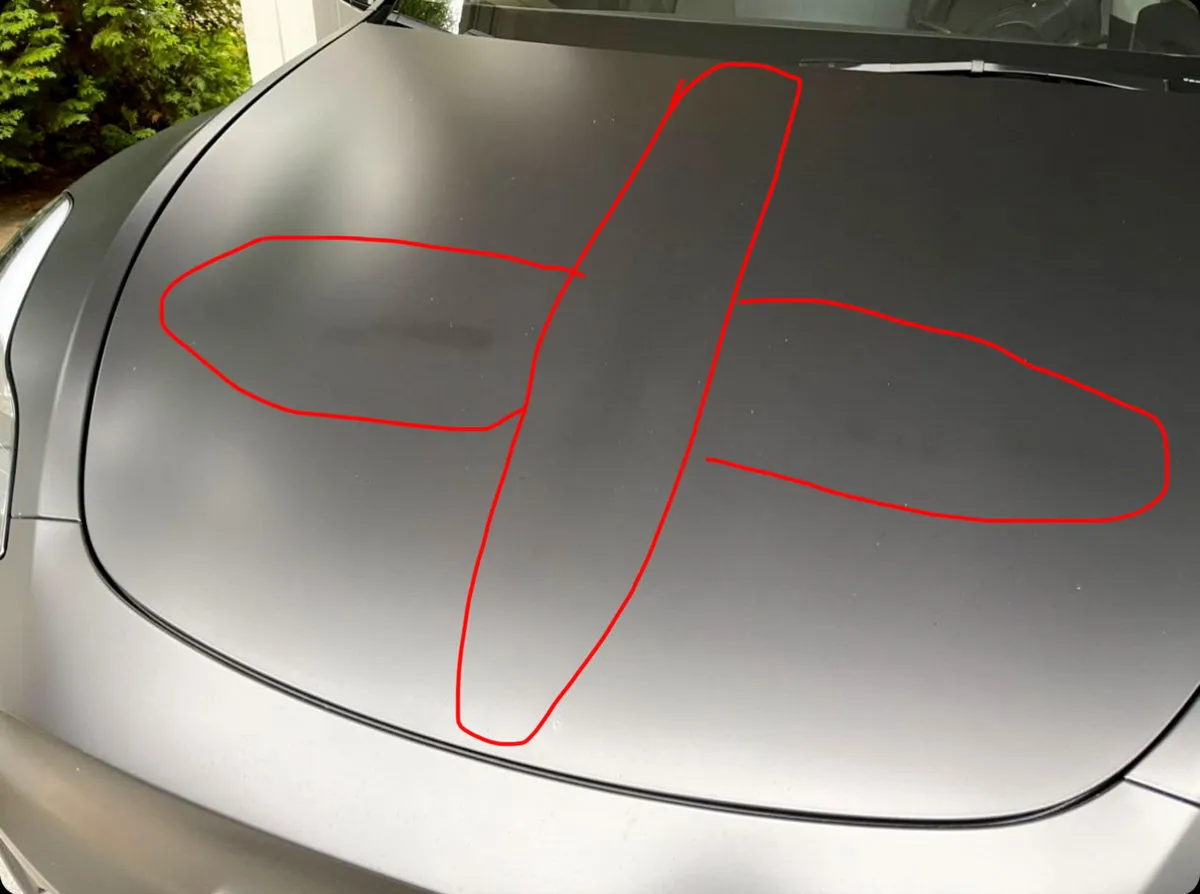

About a month after the black “BatMobile” Tesla Model Y was wrapped, the customer contacted us, reporting strange shiny streaks on the hood and sides of the car, in a systematic and symmetrical manner.

We immediately inspected the car, and our initial reaction and suspicion were that there might have been a material defect, which, while possible, is extremely rare. We provided the customer with our electric car as a temporary replacement and began the investigation process.

First, we attempted to remove the marks with cleaning chemicals. When we found that it didn’t help, we removed a piece of PPF from the hood entirely and placed a test piece in the same spot where these streaks appeared. We made an interesting observation:

When you apply matte film over a glossy surface, the surface becomes matte, as expected. In this case, however, the matte film seems to accentuate these shiny streaks compared to the rest of the paint surface. This is a peculiar phenomenon, as we’re not automotive engineers and cannot provide a technical explanation. Of course, this wouldn’t be noticeable to the naked eye when the car is new since all cars come with glossy finishes from the factory.

We observed the same phenomenon in precisely the same spots on the white Model Y, which was wrapped with matte transparent PPF. The manufacturing time for both cars was approximately 7 months apart.

In summary, if you wrap a Tesla Model Y in transparent matte or satin PPF, this aesthetic characteristic will almost certainly manifest. However, if the car is wrapped in glossy PPF, this won’t be visible.

Ultimately, we re-wrapped the hood and applied a ceramic coating to it.

After explaining the situation and analysis to the customer, we determined this was a force majeure situation, and the customer would need to adapt to the characteristics of the paint surface. The customer fully understood the situation and wanted to pay for all the effort and the re-wrapping of the hood, as technically, it wasn’t Restyling’s fault. However, we also believed it wasn’t the customer’s fault, so we politely refused to accept payment, considering this experience a lesson learned and looking positively towards the future.

Car Wash Can Be Done Wrong

While investigating this complaint, we noticed the entire car was covered in spots. These were chemical damages, and they couldn’t be removed with standard cleaners.

After investigating with the customer, we concluded that the car wash where the customer had last used their car had washed the car with a slightly erroneous washing method.

The specific mistake was that the car had been sprayed with pre-wash detergent, which had been strongly acidic and hadn’t been post-treated. While using pre-wash detergent is entirely permissible, strongly acidic substances must always be neutralized with a strong alkaline substance.

We immediately took the customer’s car in for work because time was of the essence, and every hour could be crucial for a wrap costing over six thousand euros. We treated the car overnight and managed to restore the car’s wrap surface to like-new condition. The wrap and ceramic coating were not damaged, thanks to this operation.

https://www.instagram.com/tv/CV1GZ1iAdFN/

It’s important to remember the correct washing methods. To prevent these mishaps, we provide each customer with washing instructions.

Pictures of completed Tesla Model Y wraps

Price breakdown

Thank you to the team and customers for these projects.

Do you want the work to be done responsibly, on schedule, and with the best value for your money? Ask for a quote from the professionals at Restyling Point, who carry out their work with quality standards, values, and care.

On WhatsApp: +358445050624

Phone: +358445050624

By Email: [email protected]

Restyling Point Oy – The Nordic leader in wrapping and protection treatments