- Paint Surface Inspection

- Thorough Cleaning of the Car

- Starting the Installation of the Protective Film

- Consequences of Poor Painting

- Extra Mile

- Interior Parts Protected with PPF Film

- Material Defect in Windshield Protective Film

- Bentley – Completed Artwork

Paint Surface Inspection

A 2007 Bentley Azure with 140,000 kilometers was brought to us on a flatbed directly from Monaco, France, for the application of paint protection film. Since the car arrived clean, we could start with a visual inspection for damages and abnormalities. Initially, the paint thickness was measured with a digital device, revealing that over 50% of the body panels had been repainted. Later during the project, it was discovered that the repainting had been done at Bentley Monaco.

Small stone chips and paint edges were found all over the car, which were patched with touch-up paint of the same color code to ensure they wouldn’t show under the PPF film. The touch-up paint was obtained from an auto body shop, and we also took the detached fuel tank door there for color verification. No dents were present, only a minor visible scratch underneath the bumper.

Furthermore, no traces of old ceramic coating were found on the car. This was verified using PPF film adhesion tests. Therefore, machine polishing was unnecessary, and we could proceed with applying the PPF film without polishing, significantly expediting the project start. We assessed the overall condition of the car to be excellent considering its age and mileage.

Thorough Cleaning of the Car

After our four-hour spa treatment, every nook and cranny of the car was cleaner than it had been in decades. We washed, among other things, the door gaps, the inside of the rims, the inner arches thoroughly, and rinsed the underside. Cleanliness is a crucial factor in PPF protection, which is why our facility has its own washing area where the car drives a 4-meter distance to the installation crane.

With this recipe, we minimize dirt from getting into the car and maximize quality. The importance of having our own washing area is invaluable, and many customers would like to have their cars washed here, but unfortunately, we do not offer that service yet because we focus and specialize in what we love and what we do best.

Starting the Installation of the Protective Film

Next, it was time for the taping preparations. We checked our Llumar PrecisionCut license program for pre-existing templates for the car, but they were not available in the database because the car is rare and old. It was decided to use the “Bulk” method, as per the terminology commonly used in the taping industry.

This method differs from using computer-edited templates in that it is more labor-intensive, less cost-effective in terms of material usage, and slower in the installation of protective film.

However, this didn’t bother us because the owner did not set any time limits. This allowed us to combine craftsmanship and artistry in a relaxed combination, appealing to tape installers who love handiwork.

After handcrafting the tape templates and ensuring their precise fit, we began the installation from the hood. The most challenging parts of this car were the front fenders, rear fenders, and the trunk lid.

Due to the sharp 90-degree angles of the aforementioned body parts, we had to plan and execute several test runs because we aimed for a seamless result. The easiest route would have been to work with pieces and bumper seams, but in our company, we do not choose the easiest path.

The installation of the protective film on the fenders was executed admirably.

The taillights and front grille had to be removed due to quality criteria. During the removal process, we noticed that the attachment points had been tampered with before us. This was evident from the tool marks on the bolts and nuts.

Consequences of Poor Paintwork

During the installation phase of the rear trunk lid, we encountered a surprise with a freshly painted part in one corner when the lacquer began to peel off over a few centimeters. And this happened even before the PPF protective film had been fully loaded onto it.

So, from a technical standpoint, the adhesive’s grip at the moment of lacquer detachment was only about 20% of its maximum. Lacquer peeling usually results from an inadequate painting process.

This happens extremely rarely, it cannot be avoided or anticipated, but the risks can be minimized – and that’s exactly what we did in this case without exception. We always inform our customers in advance that there is no warranty on repainted parts, and they are always done at the customer’s own risk.

Ultimately, we decided to repair the rear trunk lid to a like-new condition at Espoo Bentley, and we offered to perform the rear trunk lid re-wrapping free of charge for the customer.

Even though the fault was not technically ours, we extended a helping hand in this force majeure situation.

In Restyling Point’s business culture, the significance of money is not essential.

Extra mile

When the car’s exterior paint was fully protected with lights, it was decided to also apply protective tape to the chrome parts as a bonus, because the car’s chrome parts easily oxidize, and stones fly mercilessly under the tires, causing a sandblasting effect.

Even the small glossy black trims were taped with transparent film. We pay attention to details because we consider the shapes of cars and their most sensitive parts.

Following our business culture, instead of discounts, we provide bonus services.

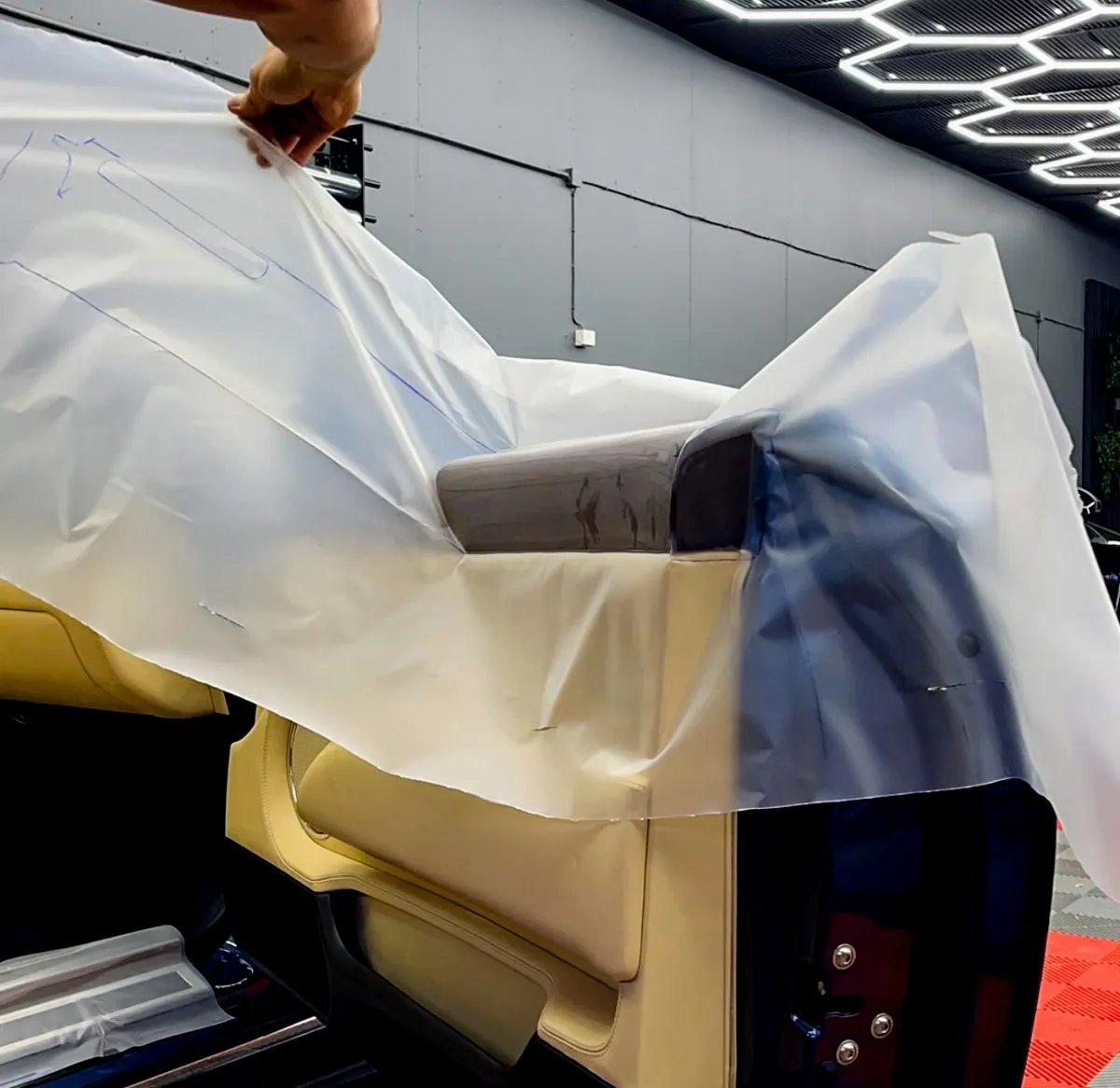

Interior parts protected with PPF film – fine woods

Our customer decided to also protect the interior fine woods, the chrome door sills, and the windshield with protective tape. None of the aforementioned parts are manufactured anymore.

It took 26 hours to work on the car’s interior because each part was pre-made as a pattern, and after a few test fittings, the PPF film was installed on the interior. Hours easily extended into overtime, aiming to meet the planned schedule.

So there were a total of 40 pieces, and each of them had small buttons and elements that cannot be detached.

In the newest cars, interior parts come off easily, which makes protective taping easier, but not in this case. Here, everything was bolted on so robustly that we decided to skip dismantling the interior after weighing the risks.

During the interior protective taping process, we switched off the subconscious time constraints and worked with complete enjoyment and maximal meticulousness because it took hours in prepping the templates, but only a few minutes for the actual installation.

In this surgical-like process, there was no room for rushing, and sometimes hours passed into the next day. The installer had to be able to focus on the core of the project, hungry at 2 o’clock in the morning.

“Phew! I’m enjoying this immensely, this is what I love. It’s all about maximum precision and delicate mechanical craftsmanship. Bring it on!” says Sergei, the CEO and installer of Restyling, who, according to his friends, has sausage fingers and nerves of steel.

We were amazed at how the high-gloss polished wood parts brightened to a new shine level and looked even glossier after the installation of the PPF protective film.

Wow! We also encountered this effect on chrome side mirrors and other chrome parts of the car.

Even the circular part of the steering wheel was covered with protective film, albeit only after the interior leather restoration. This was a separate request from the leather restoration professionals. The car owner wanted the interior of the car to be in like-new condition, so we organized a total leather restoration project for the car, where the seats and other parts were dismantled and everything was repainted. We chose two companies, both of which visited the site to assess the project, and we forwarded the job offers directly to the car owner without intermediaries.

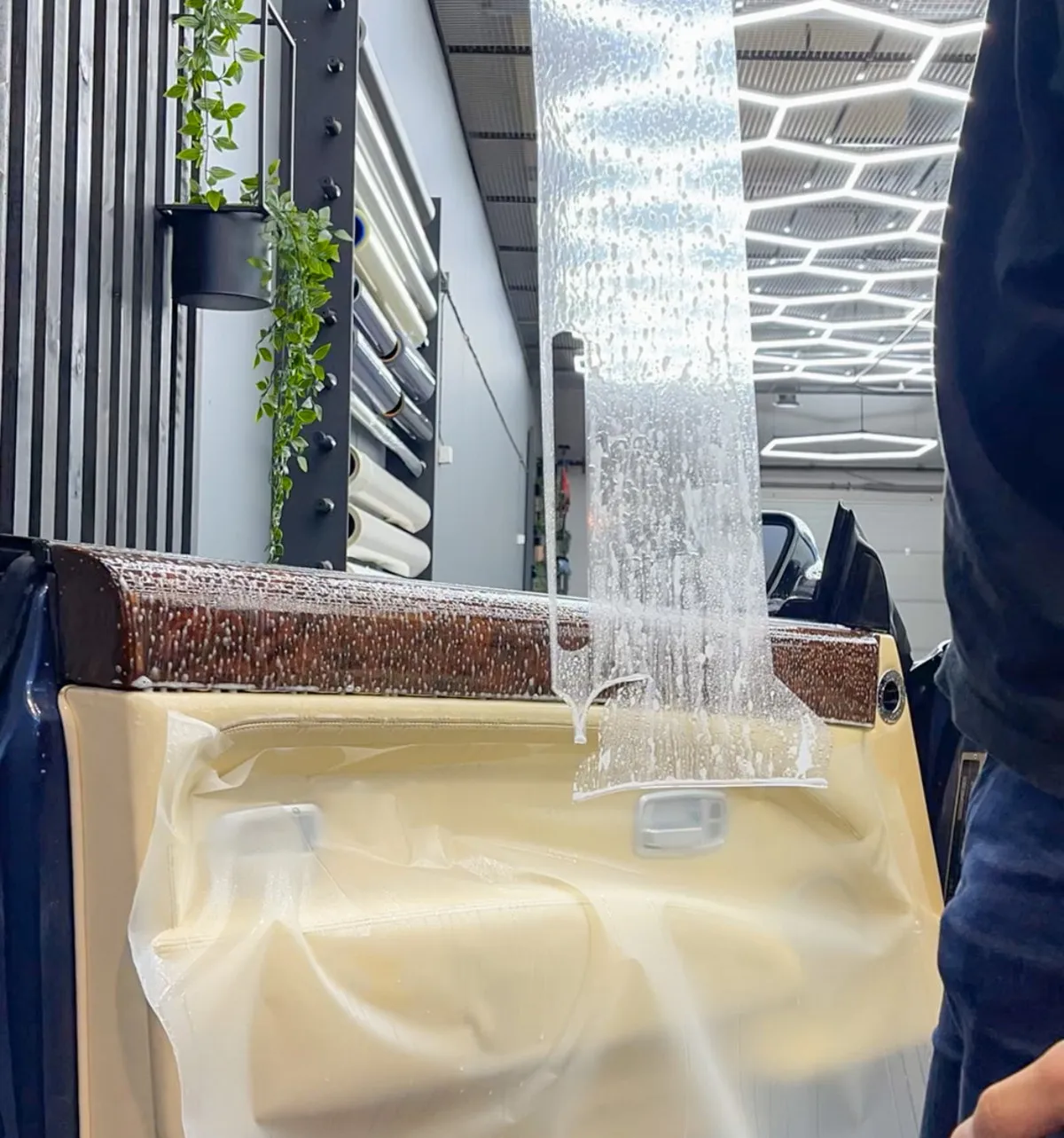

Material defect in the windshield protective film

We encountered a manufacturing defect in the windshield protective film (Stek DynoFlex), which we noticed already on the roll. We decided to postpone the installation of the windshield protective film for the time being and informed our customer about this. We initiated a complaint process with the importer and are waiting for the tape, which will arrive after the New Year. The windshield protective film will be installed once the material arrives.

Towards the end of the protective taping project, we set a goal to have the car ready before Christmas so that we could start the new year with a clean slate.

We had to keep the car charged all the time because the old battery had reached the end of its life, and inadequate battery condition is common in older cars.

The car protective taping was enjoyable and technically challenging at times, which was excellent. Dealing with daily Audis, Porsches, and Teslas has become routine. This PPF protective taping project occasionally pushed us out of our comfort zone, and this is a wonderful thing. More of these, please, thank you.

“Move out of your comfort zone. You can only grow if you are willing to feel awkward and uncomfortable when you try something new”

– Brian Tracy

Bentley Azure – completed masterpiece

Overall, the project went commendably well, and we managed to celebrate Christmas after delivering the car to the customer before the holidays.

We are pleased with the work completed, and so is the customer. The car’s shine improved, and most importantly, the tape is not noticeable at all. It’s great to hand over yet another collector’s car back onto the road. Now it is maximally secured and insured with Restyling’s method, which even insurance companies cannot match.

In collector cars, the challenge lies in the availability and existence of parts. With the tape, we removed unnecessary risks and preserved the original condition for decades.

For a loyal customer, who brought their fifth car, the price was formed as follows:

€6000 for the best protective treatment of the car’s exterior paint.

€1300 for the protection of the 40 pieces of interior fine wood parts.

€380 for the interior door sills.

€69 for the acquisition of touch-up paint.

Over the years, we have witnessed numerous situations where a car is brought to us with surface damage, and the distressed owner requests us to immediately remove the PPF protective film to check if the damage has reached the paint. This is a rather interesting situation.

Many clearly fear trusting the abilities of the PPF film, and when we start pulling the film off, their eyes light up, and the burden lifts off their shoulders. There is no damage underneath the film. The car doesn’t need repainting! It’s a great feeling for us to see our product working year after year.

Can even a hundred layers of ceramic coating achieve this?

Read more about the differences between PPF protective film and ceramic coating here. (What is the difference between ceramic coating and PPF paint protection film?)

The dashboard plastic part pattern creation and protective film installation took 8 hours. Precise craftsmanship.

Car brand – Bentley Motors

Would you like the work to be done responsibly, on schedule, and with the best value for your money? Ask for a quote from the professionals at Restyling Point, who perform this with quality standards, values, and love.

On WhatsApp: +358445050624

Phone: +358445050624

By Email: [email protected]

Restyling Point Oy – Leading in wrapping and protection treatments in the Nordics